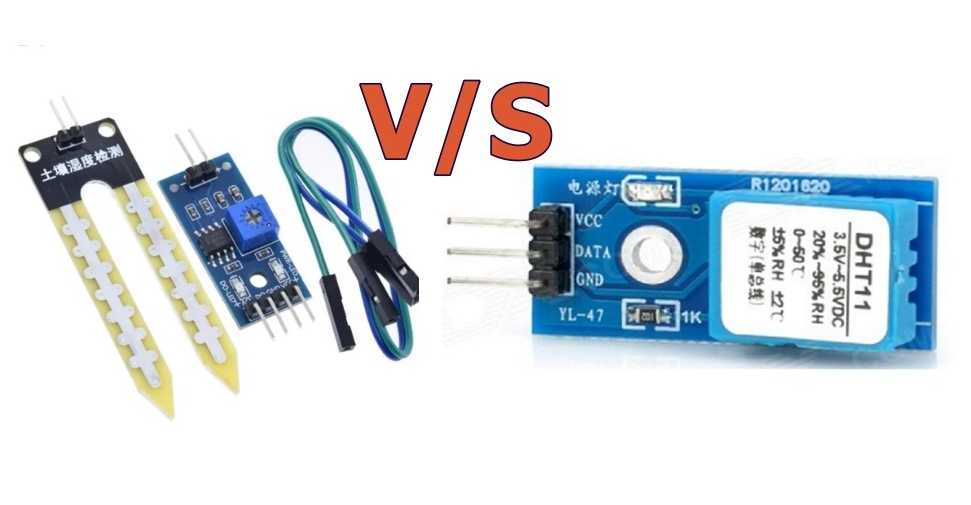

When it comes to maintaining optimal water levels for plants, irrigation systems rely on sensors to monitor water usage and efficiency.

Among these, humidity and moisture sensors play a crucial role.

While both types of sensors detect water presence, they differ in their specific applications, measurement techniques, and the type of information they provide.

This blog post explores the distinctions between humidity and moisture sensors, their working principles, and the scenarios where each sensor is most beneficial.

What Is a Humidity Sensor?

Humidity Sensor measures the water vapor present in the air.

It provides the RH (Relative Humidity) data, which is the ratio of the amount of moisture present in the air to the maximum amount of moisture the air can hold at a specific temperature.

RH data helps to prevent issues, such as mold growth, corrosion, and discomfort caused by high or low humidity levels.

Humidity Sensors are used in a variety of applications, including:

Heating, Ventilation, and Air Conditioning (HVAC) systems:

By regulating the moisture in the air, Humidity sensors help maintain comfortable indoor air quality.

Greenhouse and Controlled Environment Agriculture:

For greenhouse and other temperature-sensitive plants, it is important. Precise humidity control is crucial for optimal plant growth and disease prevention.

Residential and commercial buildings:

Humidity sensors are often integrated into smart home and building automation systems to maintain comfortable living and working environments.

Working Principle of Humidity Sensor

Capacitive humidity sensors:

These sensors measure humidity by detecting changes in the dielectric properties of a moisture-sensitive polymer or ceramic material. As the humidity level changes, the capacitance of the sensor changes accordingly.

Resistive humidity sensors:

Resistive humidity sensors rely on the principle that the electrical resistance of a hygroscopic material (a material that absorbs or releases moisture) changes with variations in humidity levels.

Thermal conductivity humidity sensors.

These sensors measure humidity by monitoring the change in thermal conductivity of a dry gas compared to a humid gas. The thermal conductivity of humid air is higher than that of dry air.

Gravimetric humidity sensors:

Gravimetric sensors measure humidity by detecting changes in the mass of a hygroscopic material as it absorbs or releases water vapor.

What Is a Moisture Sensor?

A moisture sensor is your go-to gadget for checking how damp or dry things are, whether it’s soil, wood, concrete, or anything else that likes to soak up water.

It can be a physical sensor that measures the water content by weight or volume, or it can be a chemical sensor that reacts to changes in moisture levels.

Moisture sensors have many use cases in a variety of applications:

Agriculture and irrigation systems:

Moisture sensor helps growers optimize irrigation efficiency and ensure efficient irrigation practices by measuring the water content in the soil.

Construction and building monitoring:

Moisture sensors are used to detect water leaks, monitor concrete curing, and assess the moisture content of building materials.

Horticulture and Landscaping:

For optimal plant growth, maintaining the water level is crucial in Horticulture, as well as preventing over or under-watering.

Wood and paper industries:

Moisture sensors help control the moisture content of wood and paper products to ensure optimal quality and prevent damage.

Leak Detection System:

Moisture sensors precisely detect water leakage in pipes, other appliances, and other systems, allowing for timely repair and preventing water damage.

Working Principle Of Moisture Sensor

There are several types of Moisture sensors available, each utilizing different principles to measure water content in solid materials. The most common types include:

Resistance-based moisture sensors:

These sensors measure the electrical resistance of the material, which varies depending on its moisture content. Dry materials have higher resistance, while wet materials have lower resistance.

Capacitance-based moisture sensors:

Capacitance-based sensors measure the dielectric constant of the material, which changes with varying moisture levels. The higher the moisture content, the higher the dielectric constant.

Neutron scattering moisture sensors:

These sensors emit neutrons into the material and measure the amount of neutron scattering, which is influenced by the hydrogen content (and thus the moisture content) of the material.

Thermal conductivity moisture sensors: Similar to humidity sensors, these sensors measure the thermal conductivity of the material, which changes with varying moisture levels.

Time Domain Reflectometry (TDR) moisture sensors:

TDR sensors measure the propagation time of an electromagnetic wave along a waveguide or probe inserted into the material. The propagation time is affected by the material’s moisture content.

Key Differences Between Humidity and Moisture Sensor

| Differences | Humidity Sensor | Moisture Sensor |

|---|---|---|

| Areas Used | Humidity Sensors are primarily used in environmental monitoring, HVAC systems, and industrial processes where air quality and humidity control are essential. | Moisture sensors, on the other hand, are used in applications involving solid materials, such as agriculture, construction, and leak detection. |

| Measurement Medium | As a name Humidity sensor measures the water vapor in the air. | Where moisture sensors measure the water content in solid materials (liquid or bound state). |

| Measurement Unit | Humidity sensors typically measure relative humidity (RH) as a percentage. | Moisture sensors measure water content or moisture levels in various units, such as volumetric water content (VWC), gravimetric water content (GWC), or specific moisture content. |

| Working Principle | Humidity sensors rely on principles such as capacitance, resistance, thermal conductivity, or gravimetric changes in response to water vapor in the air. | Moisture sensors measure electrical properties like resistance, capacitance, or time-domain reflectometry to detect water content in solid materials. |

| Installation | Humidity sensors are typically installed in open spaces or air ducts to measure the ambient air humidity. | Moisture sensors often require direct contact with or insertion into the solid material being measured, such as soil, wood, or concrete. |

Choosing the Right Sensor For Your Application

Choosing the correct sensor for your usage needs is a tough one.

Take humidity sensors, for instance. They’re awesome for keeping tabs on air quality in places like HVAC systems, greenhouses, and factories. But if you’re dealing with stuff like soil or concrete, moisture sensors are where it’s at – they’re perfect for agriculture, building, and spotting leaks.

In some cases, humidity and moisture to obtain a comprehensive understanding of the water content in different states. For example, in greenhouse applications, both air humidity and soil moisture levels need to be monitored and controlled for optimal plant growth.

It is also important to consider factors such as sensor accuracy, response time, durability, and compatibility with your existing monitoring and control systems when choosing the appropriate sensor type.

Final Thoughts…

Understanding the differences between humidity and moisture sensors is essential for selecting the right sensor for your application and ensuring accurate measurements.

By leveraging the capabilities of both sensor types, you can effectively monitor and maintain optimal environmental conditions across various industries, from agriculture and construction to HVAC and industrial processes.

Leave a Reply